Get your Monitoring Challenge under Control using Acoustic Emission Solution

THE DEMAND – In order to identify structural defects or critical conditions in aging industrial assets and new constructions the demand for SHM rises.

THE CAUSE – Corrosion of reinforcing tendons in concrete structures has a negative impact on safety and operability.

THE LIFETIME OPTIMIZATION – Monitoring systems can offer operational optimization and possible lifetime extension of assets. This valuable tool for operators helps to manage financial, environmental and human risks.

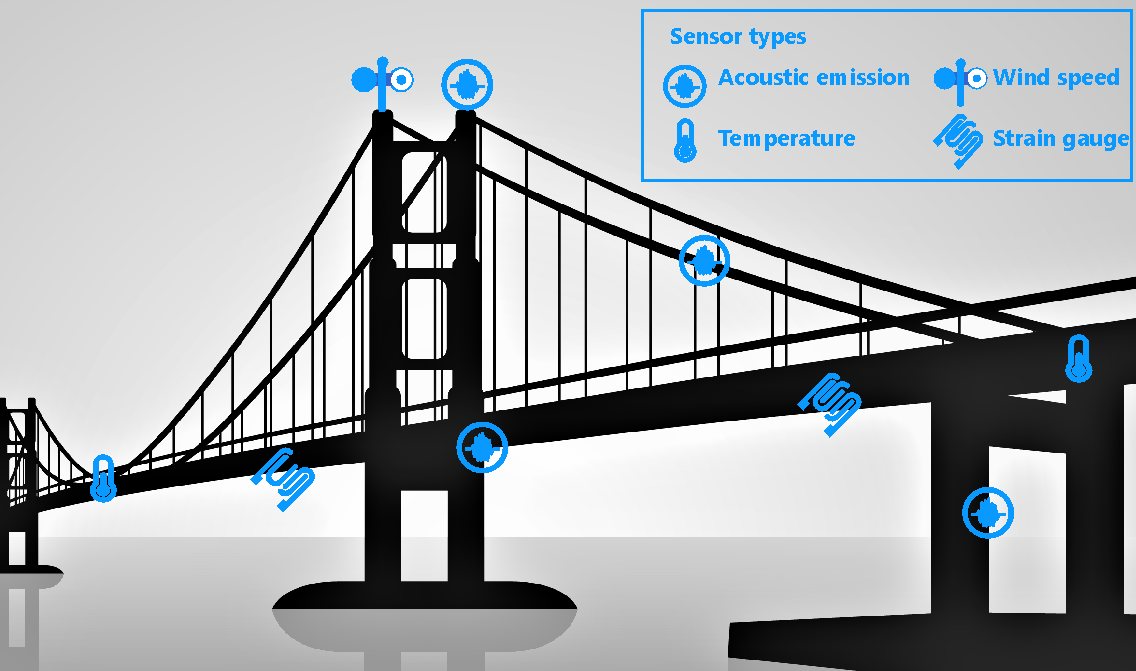

THE REALIZATION – Critical “hot spots” are equipped with appropriate sensors for monitoring and analyzing activities inside.

THE SOLUTION – Using Vallen Systeme´s Acoustic Emission solution, you´ll get your monitoring challenge under control using only one measurement system.

Your Benefits

1. Detection and location of defects during operation

2. Monitoring of hidden and remote flaws

3. Real-time monitoring 24/7 and early warning

4. Integration and analysis of various sensor types in one system

5. Customized solutions

6. Improved risk and maintenance management

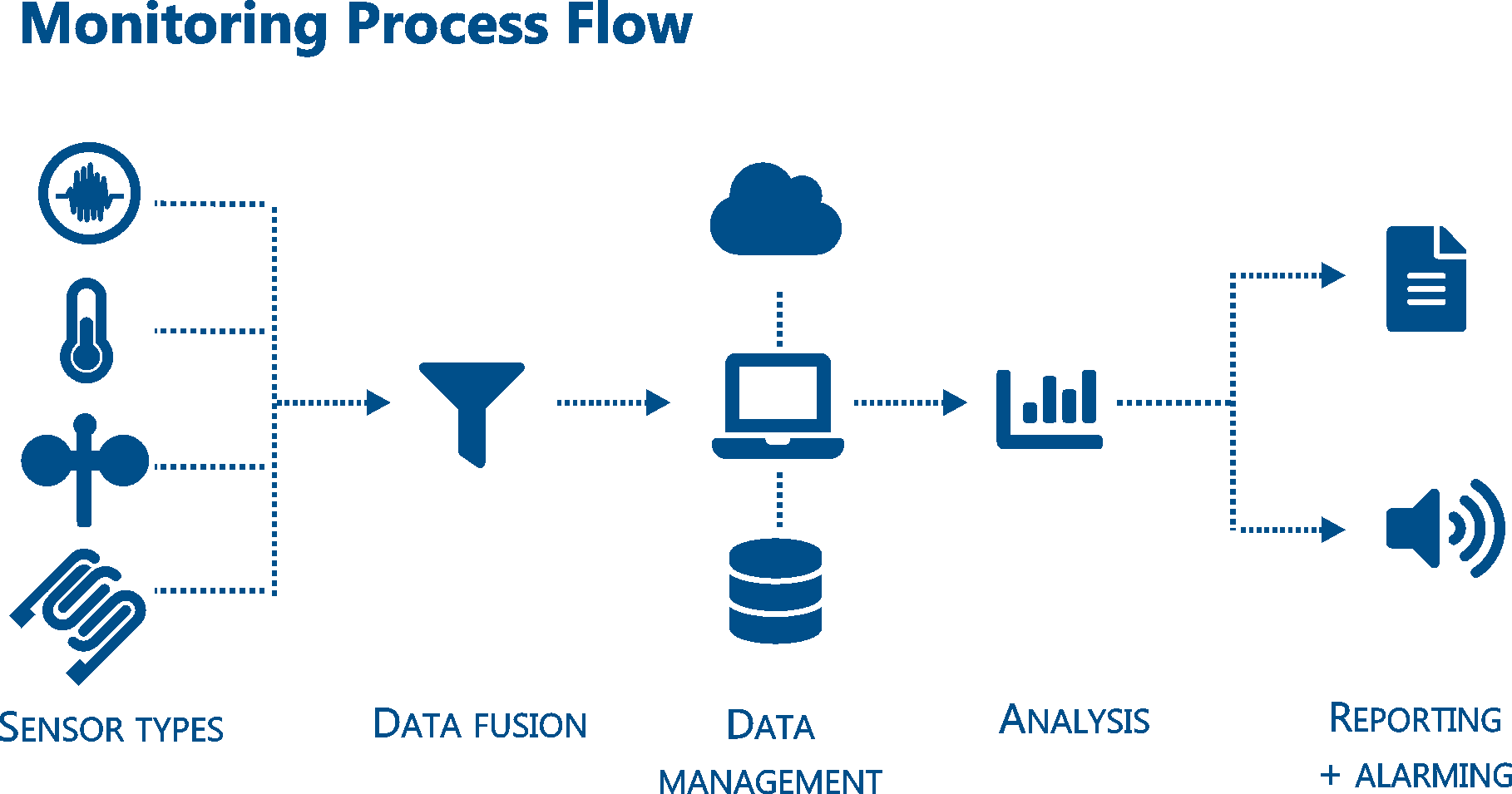

Monitoring Process Flow

SENSOR TYPES AND DATA FUSION – Data fusion of various sensor types, e.g., for temperature, wind speed or strain gauge measurement, can be totally integrated by the data logger.

DATA MANAGEMENT AND ANALYSIS – Data are conveniently analyzable together with acoustic emission data by Vallen Monitoring Software. Data storage in the cloud and remote control are given.

REPORTING AND ALARMING – Results are reported and an alarm is triggered.

Your Vallen Systeme´s Acoustic Emission Solution

THE CUSTOMIZING – Your customized monitoring solution can be realized in several steps via solution development by a project team consisting of Vallen Systeme, a service provider, and engineering consultants.

THE VALLEN SYSTEME´S PERFORMANCE – Vallen Systeme provides acoustic emission equipment and engineering services in monitoring projects for operators, consulting engineers, service providers and public authorities.

THE EXPERTISE – Many years of experience in feasibility studies and various projects have resulted in continuous improvement and tailored measurement chains.

THE ADJUSTMENTS – Sensors, their mounting devices and cables, as well as data acquisition and software features are adjusted to the new demands which makes the measurement system applicable in various 24/7 real-time monitoring projects.